The term “tribology” was first introduced by Peter Jost in 1966 through his landmark report, the Jost Report. This report defined tribology as the interdisciplinary study of surfaces in relative motion, encompassing critical elements such as friction, wear, and lubrication. Since then, tribology has become an indispensable field in modern engineering and materials science.

Tribotesting is a fundamental aspect of tribology, involving the experimental evaluation of friction, wear, and lubrication. It is essential for assessing the performance of materials and lubricants under conditions that replicate real-world applications. From automotive engineering to aerospace, biomedical devices, and manufacturing, tribotesting ensures that materials and systems meet strict durability and efficiency standards.

Modern machine design is incomplete without considering tribological factors, as they play a crucial role in optimizing performance and longevity. Tribotesting uses a variety of experimental techniques to measure properties like friction coefficients, wear rates, and lubrication effectiveness.

The first commercially available lubricant test equipment, the Pin and Vee Block Tester, was introduced by Falex in 1927. This apparatus was developed to scientifically quantify the anti-wear and extreme pressure properties of both fluid and solid lubricants. Since then, tribotesting techniques have evolved significantly, with the most commonly used methods today including: Pin-on-Disc Test, Four-Ball Tester, Reciprocating Tribotester, Block-on-Ring Tribotester

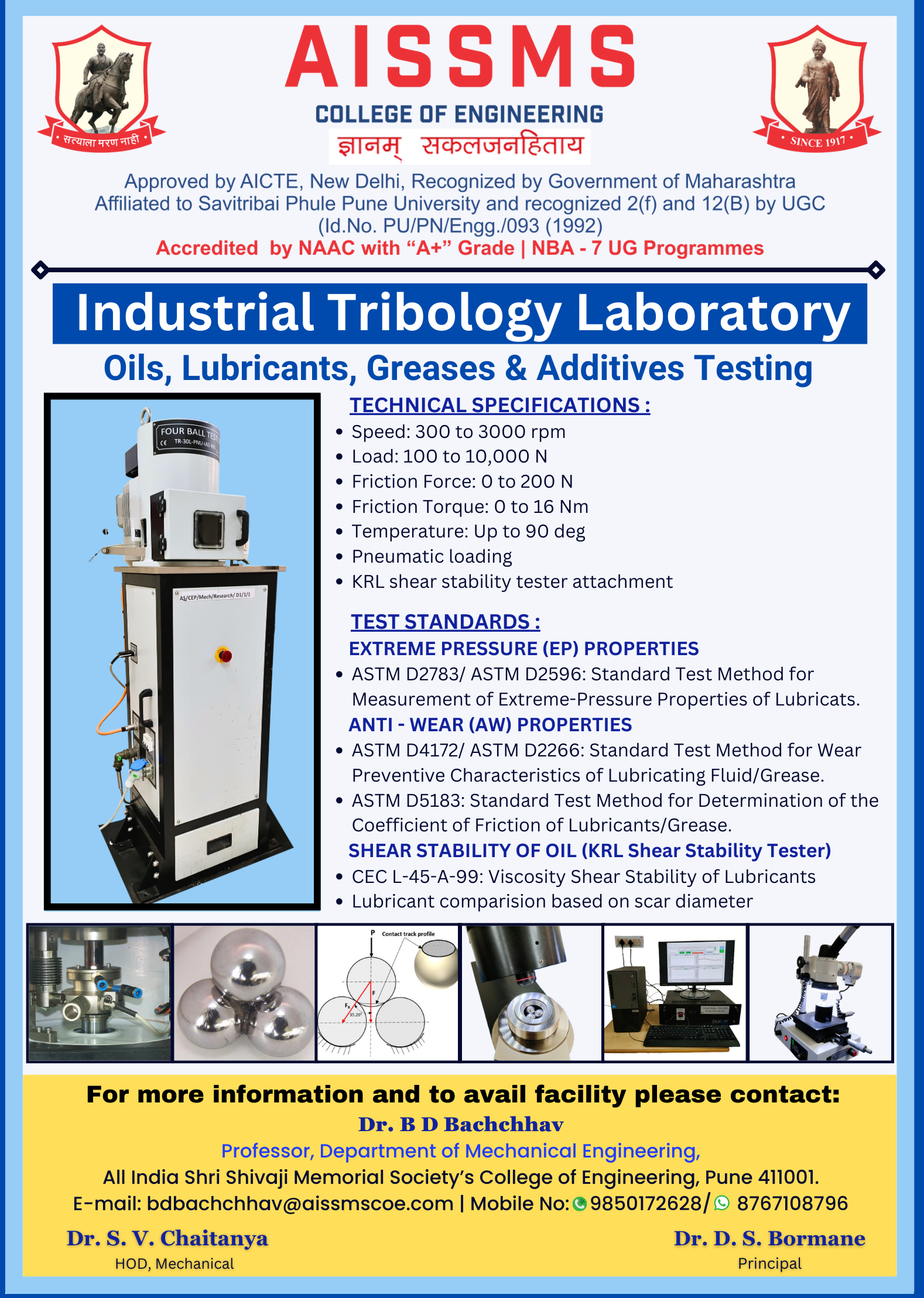

Oil analysis laboratories and portable testing equipment now allow lubrication professionals and maintenance managers to quickly and accurately assess the health of systems and lubricants. These tools use a combination of methods, including chemical analysis, ultrasonic measurements, and spectrographic techniques, to evaluate performance. For example, friction and wear characteristics of lubricating oils can be evaluated using the Four-Ball Tester, following ASTM standards such as ASTM D2783, ASTM D2596, ASTM D4172, and ASTM D2266.

To support research and education, AISSMS College of Engineering, Pune, offers advanced lubricant testing facilities. These resources cater to the needs of mechanical and production engineering faculty, post-graduate students, research scholars, practicing engineers, and lubricant manufacturers.

The field of tribotesting continues to evolve, driven by advancements in technology and emerging applications. Key trends include: Exploring friction and wear properties at the nanoscale, especially for nanotechnology applications, Real-time analysis of wear and friction using advanced sensors, Predictive material behavior modeling and optimization of test parameters, and the development of biotribology for biomedical devices and applications. These emerging areas offer exciting opportunities for researchers to explore and expand the boundaries of tribology.

Tribotesting is an invaluable tool for ensuring the reliability and performance of materials and lubricants across diverse industries. With advancements in testing techniques and growing opportunities for research, tribotesting continues to shape the future of engineering and material science.

Written By:

Dr. Bhanudas D Bachchhav

Professor, Department of Mechanical Engineering,

All India Shri Shivaji Memorial Society’s College of Engineering, Pune